أرسل لنا رسالة

finish mill grinding cement production process

cement manufacturing

Cement grinding. The clinker from the pyroprocessing area is ground in ball mills or roll press + Ball mill combination or vertical roller mills to form cement. Commonly used separators are in closed circuit grinding are: O –sepa, Sepol and Sepax separators to achieve a finish cement fineness of 3000 – 4000 Blaine surface (cm2/gm).

Portland Cement Manufacturing

acquisition and handling, kiln feed preparation, pyroprocessing, and finished cement grinding. Each of these process components is described briefly below. The primary focus of this discussion is on pyroprocessing operations, which constitute the core of a portland cement plant. The initial production step in portland cement manufacturing is ...

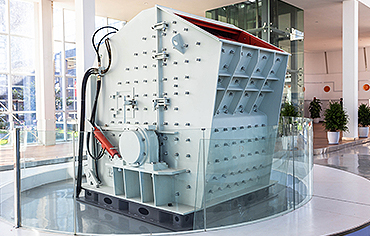

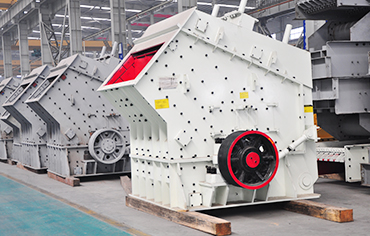

Finish Mill Cement Plant | Crusher Mills, Cone Crusher ...

finish mill grinding cement production process | Ore Mining. Cement grinding plant includes all kinds of powder mill. – Get More or Get Price – . cement finish mills, Raymond bowl mills.

JK Lakshmi Cement Manufacturing Process YouTube

Sep 14, 2014· Cement Manufacturing Process ACC Limited Duration: ... ACC North 53,302 views. 2:21. LOESCHE Compact Cement Grinding Plant (CCG Plant) Duration: 4:27 ... How Ball Mills .

finish mill grinding cement production

finish mill packing cement Finish grinding (OK mill) finish machining production main products include half gear,support roller,tyres for cement . The cement mill. Brief description of a cement mill. Clinker grinding uses a lot of energy and the cement to get a clear picture of a complex process like cement production. Finish Mill ...

Production process of Mir Cement | Mir Cement Limited

Cement Finishing Process: The final process of cement making is called finish grinding. Clinker dosed with controlled amount of gypsum is fed into a Ball Mill, a horizontal steel tube filled with steel balls. As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder.

Cement Grinding and Milling Systems Course

The concept of grindability and the effects of intergrinding materials of different grindability; Drying and evaporative cooling; The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process.

EnergyEfficient Technologies in Cement Grinding | IntechOpen

EnergyEfficient Technologies in Cement Grinding ... provided insights into the operational and sizereduction characteristics of Horomill® and HPGR/twocompartment ball millgrinding process with indications that Horomill® application could produce the same type of pozzolanic portland cement at lower grinding energy requirement ...

Présentation PowerPoint Lafarge

So, the raw mix is burnt to produce clinker : the basic material needed to make cement. conveyor Next Raw mix kiln cooling Back preheating clinker storage at the plant Raw mill THE CEMENT MANUFACTURING PROCESS : The clinker and the gypsum are very finely ground giving a "pure cement".

Stage 4: Finish Process | Cement Production

Greater Detail: Cement Plant Operations Handbook Crewmen''s Guide, Finish Mill Systems Cement mill A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage[1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement..

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

Finish Mill Process Of Cement Crusher Usa

Finish Mill Cement Plant Crusher Mills Cone Crusher Finish mill cement manufacturing process in finsh mill crusherA cement mill or finish mill in north american usage cement manufacturing process components of a cement plant from quarry to kiln to cement the equipment used to grind the hard cement machinery we are leading cement plant.

Mill Grinding Course and Kiln Process Program

Cement Manufacturing Capacity, February 2017 "The Wall" Impact on Cement Consumption, February 2017; ... Mill Grinding Course. PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course.

Finish Mill Grinding Cement Production Process

Finish grinding vertical mill or ball mill circuit 2 cement grinding overview pavilion differentiators the pavilion8 cement grinding application solution from rockwell automation enables continuous and dynamic optimization of the cement grinding process t,Finish mill grinding cement production process.

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. ... Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills. Further, it is packed to about 2040 kg bags. Only a small percent of cement is packed in the bags only for those customers whom need is very small.

process of cement grinding

The Cement Production Process mcilvainecompany. Finish grinding or milling (the process of grinding clinker) has different requirements to raw grinding or milling (the process of milling the raw material) In general, the milling technology for clinker grinding is designed to achieve a smaller particle size than is required for the raw material

finish mill grinding cement production

Finish Mill Grinding Cement Production semifinish grinding roller press circuit finish grinding vertical mill or ball mill circuit 2 cement grinding overview pavilion differentiators the pavilion8 cement grinding application solution from rockwell automation enables continuous and dynamic optimization of the cement grinding process ...

Grinding mill for cement production YouTube

Dec 12, 2016· In cement plant, roller cement mill is very important since most of the raw materials will have to be crushed before being used to Finish Mill Grinding Cement Production Process Process Finish ...

Cement Production Process SlideShare

Sep 17, 2015· A brief information about the process of Cement Production. ... Cement Production Process 1. By: Deepesh Kumar Mishra Satna Cement Works Birla Corp. Ltd. Six Weeks Training Report ..., combined grinding and drying plants, finishing mills and raw mills through water injection. 08 Kiln A kiln is the heart of any cement plant. It is ...

What Is the Cement Manufacturing Process? (with pictures)

Jan 15, 2020· Grinding is the next step in the cement manufacturing process, and it can occur in either wet or dry forms. Wet grinding involves combining all of the materials in a mill with water and grinding it into slurry. In contrast, dry grinding processes combine and grind the materials without water, creating a substance known as kiln feed.

Highefficiency cement grinding International Cement Review

Figure 1 presents a typical process flowsheet of a finishgrinding system. The grinding plant can also be equipped with a ball mill following the POLYCOM. This is called a combigrinding circuit. The main feature of such a system is the pregrinding of cement clinker in the POLYCOM and a final grinding in the ball mill.

cement manufacturing process in finsh mill

A cement mill (or finish mill in Cement milling is the largest user of electric power on a cement plant, and because they can easily be started and stopped, Cement manufacturing components of a Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

An Introduction to Clinker Grinding and Cement Storage ...

Clinker Grinding. The cement clinker is ground as finished cement, in a vertical roller mill for cement or in ball mills similar to those normally used for grinding hard raw materials in dry and semidry processes. However, the cement clinker is more difficult to .

Manufacturing Process – Continental Cement

Step 6 : Finish Grinding. The clinker is ground in a ball mill—a horizontal steel tube filled with steel balls. As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder. It can now be considered Portland cement. The cement is so fine it will easily pass through a sieve that is fine enough to hold water.